When you’re running a pipe-manufacturing line that supplies high-pressure steel pipes, efficiency isn’t just about speed—it’s about repeating quality reliably, minimising downtime, and giving your customers confidence. A well-chosen hydrostatic testing machine for steel pipes becomes a critical tool in achieving that. Below I’ll walk through how the right machine can significantly boost your production efficiency, what features you should look for, and how it ties into your overall manufacturing workflow.

Why “suitable” matters

You might assume that any hydrostatic pressure test machine will do the job. But when you press it into a high-volume steel pipe production scenario—various diameters, wall thicknesses, export specifications, traceability requirements—you quickly see the difference between a generic machine and one tailored for your needs. The right machine will match your pipe sizes, your test pressures, your throughput, and your documentation standards. That alignment is what delivers efficiency gains, rather than just ticking a box.

Efficiency gains you can expect

Here are some concrete ways a suitable machine improves your production efficiency:

-

Shorter test cycles: Modern machines with automated clamping, fast fill/bleed systems and digital pressure ramp-up reduce the time each pipe spends in the test station. For example, one case study shows inspection time cut by nearly 50 %.

-

Higher throughput: Because the machine is matched to your pipe diameter and wall thickness range, you avoid bottlenecks where the machine is too slow or needs frequent adjustment. One source states that using a machine designed for steel-pipe testing allowed simultaneous testing of multiple pipes, improving testing efficiency.

-

Reduced scrap & rework: A machine with precise pressure control, good sealing/clamping, and reliable data capture helps detect defects at test time rather than after shipping. This avoids the scrap of good pipe or the rework of bad pipe later. For example, one article lists “defect detection, efficient testing” among key machine benefits.

-

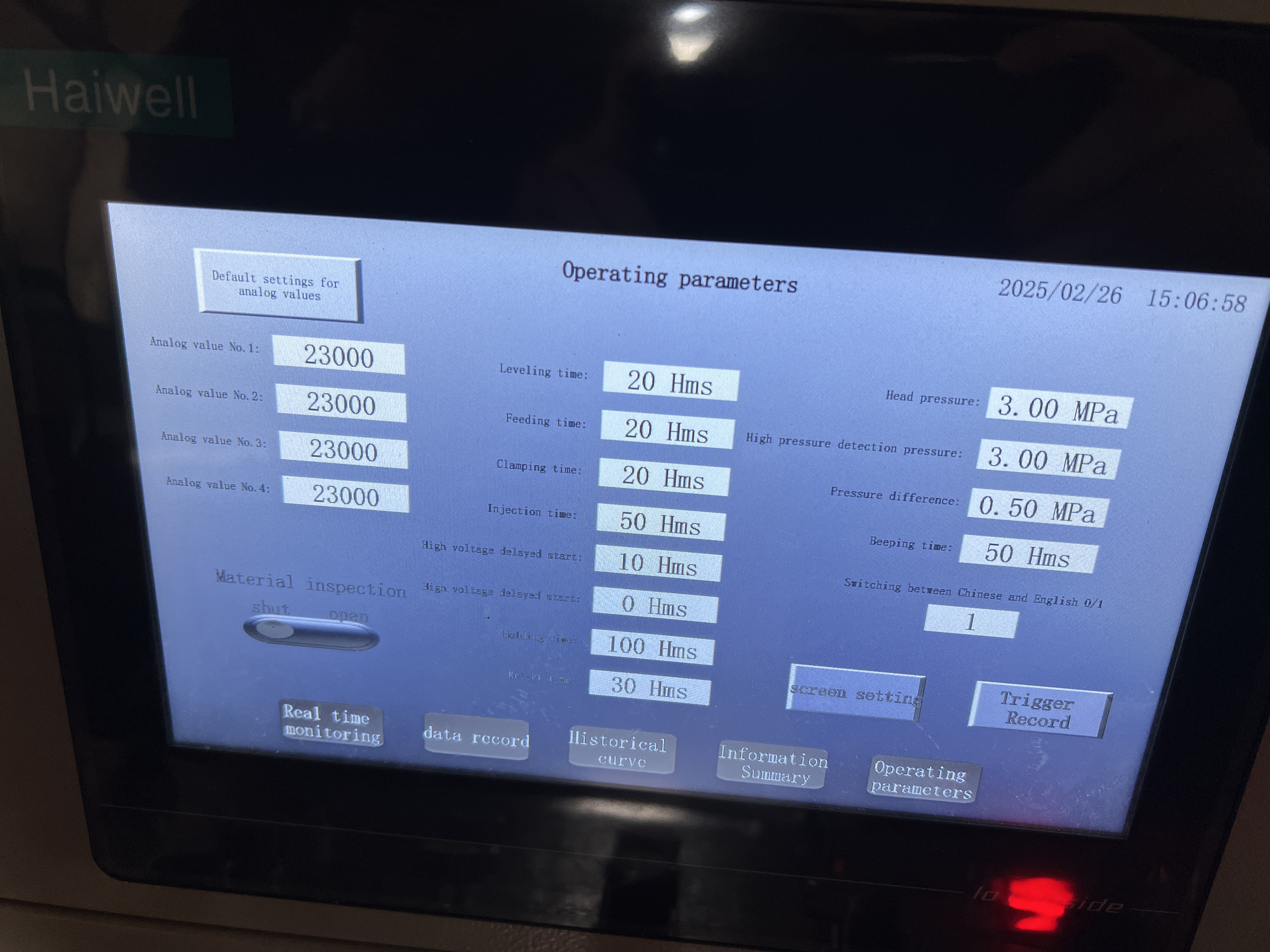

Better data and less manual work: When the machine logs pressure vs time, records test parameters automatically, and integrates with your quality systems, your operators spend less time writing reports and more time keeping the line moving. Modern machines offer digital control and real-time monitoring.

Table: Key Features vs Efficiency Benefit

|

Feature of Hydrostatic Testing Machine |

How It Improves Production Efficiency |

|

Fast fill and venting system |

Reduces idle time between tests; faster cycle start-to-finish |

|

Automatic pressure ramp and hold logic |

Minimises human error and test setup time |

|

Multi-station or parallel test capability |

Increases number of pipes tested per time unit |

|

Digital data capture & report generation |

Less manual documentation; faster hand-off to next process |

|

Robust clamping/sealing designed for your pipe specs |

Fewer false rejects, fewer retests, less downtime |

Practical tips for selecting & using your machine to maximise efficiency

Since you’re engaged in the steel pipe export business (to markets such as India, Middle East, Southeast Asia) and you also handle website-optimization (so product visibility matters), here are some actionable tips:

-

Match machine specs to your pipe mix: Don’t buy a “one-size-fits-all” machine unless that truly fits your pipe types. If you produce multiple diameters and wall thicknesses, ensure the machine handles them or has quick change-over. The article from “Key Features …” emphasises diameter & length capability matter.

-

Plan for throughput not just capacity: It’s not just maximum pressure that matters—consider how many pipes per hour the machine can realistically test, including setup time. The “inspection time cut by 50 %” example shows the impact.

-

Automate data and traceability: Clients, especially in export markets, expect test certificates, trace logs and proof of compliance. Incorporate a machine that logs automatically so you aren’t bottlenecked by paperwork.

-

Train operators and integrate with line workflow: Even the best machine won’t reach full efficiency if your operators are slow or if the machine is placed in an awkward part of the line. Align the machine’s location, the material flow, operator access and data workflow.

-

Monitor and review performance: Once installed, track metrics—e.g., test-station time per pipe, number of retests, failure rates, downtime. Use these to fine-tune machine settings, maintenance schedules, and operator training.

-

Promote the efficiency advantage in your marketing: Since you’re an exporter and website-optimization specialist, make sure your site highlights how your hydrostatic testing machine helps you deliver faster, more reliable production, and how that benefits your customers in turnaround time and quality assurance.

Why your customers care—and why you win

Your customers (in India, Middle East, Southeast Asia, etc.) are increasingly quality- and schedule-driven. When you can say: “Our steel pipes were hydro-tested using a machine configured for high throughput, full data logging, and compliant with your standards,” you stand out. The efficiency of your production line means faster delivery, fewer delays, fewer surprises—and that translates into trust and repeat business.