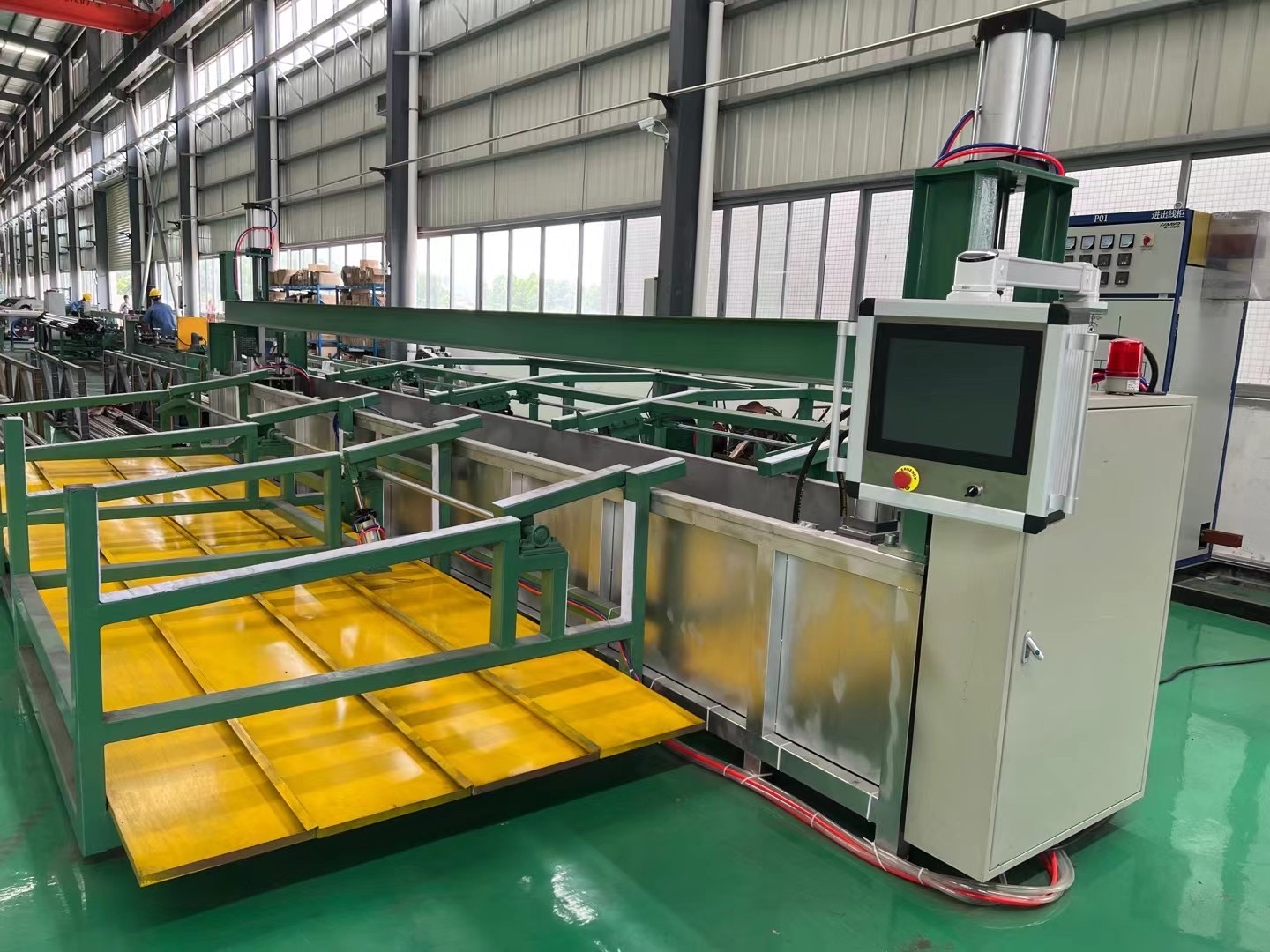

When you walk into a modern pipe production workshop, you’ll notice a trend: machines that used to require constant operator attention are now doing most of the work themselves. One key reason is the integration of PLC systems — and nowhere is this more visible than in the advanced hydro testing machine for pipe.

A PLC (Programmable Logic Controller) is essentially a rugged industrial computer designed to handle real-time automated control of machinery. Its role in a hydro testing machine for pipe is central — from automating test sequences to improving accuracy, safety, and data traceability. Let’s break down how PLC systems are elevating pressure testing in today’s manufacturing world and why they matter to quality teams and plant managers alike.

What a PLC System Actually Does

At its core, a PLC acts as the brain of a hydro testing machine for pipe. It receives inputs from various sensors — like pressure transducers, limit switches, and safety interlocks — and makes decisions based on programmed logic. It then sends commands to actuators, pumps, and valves to control the test cycle with precision and repeatability.

In contrast to older machines that depended on manual valve adjustments and analog gauges, PLC-controlled hydro testing machines allow:

-

Automated test sequences

-

Real-time pressure control

-

Digital data logging and reporting

-

Enhanced safety monitoring

This transition from manual to automated operation is a big leap forward in quality inspection systems.

Automated Test Execution and Repeatability

One of the biggest advantages of embedding a PLC into a hydro testing machine for pipe is consistency. With PLC control, each test cycle follows the same programmed sequence:

-

System checks begin

-

Water fills and air vents close

-

Pressure ramps up at a set rate

-

Test pressure holds for a defined duration

-

Pressure releases in a controlled manner

This removes much of the guesswork and variability that comes with manual control. For quality managers, consistent test execution means fewer outliers and more reliable results across every batch of pipe passing through the machine.

Real-Time Monitoring and Data Recording

Another major benefit is the way PLC systems handle data. On a modern hydro testing machine for pipe, sensors continuously send pressure and status values back to the controller. The PLC can then:

-

Compare live values to set thresholds

-

Capture pressure curves over time

-

Trigger alarms if values exceed safety limits

-

Save test records automatically to local memory or a connected database

This level of data capture is invaluable during audits or when you need to provide traceable quality documentation for customers or regulatory bodies.

Enhanced Safety and Fault Detection

Pressure testing carries real risks, especially at higher pressures. A PLC improves safety in a hydro testing machine for pipe by constantly evaluating sensor feedback and shutting the system down if something goes wrong — for example, if pressure rises too fast or a sealing condition fails. Automated logic can prevent damage to the machine and protect operators by activating relief sequences or halting the test early.

This automatic response is far more reliable than depending on operators to react manually when something unexpected happens.

Flexible Configuration and Process Control

Every pipe specification is different — varying lengths, diameters, wall thicknesses, and test pressures all demand flexibility. A PLC lets you program and store multiple test profiles for different pipe types in a hydro testing machine for pipe, so operators can select the right test scenario with a button press. That flexibility saves time, reduces setup errors, and allows the machine to adapt seamlessly to varying production demands.

Supporting Integration With Digital Systems

In a digital factory or smart manufacturing environment, PLC systems don’t work in isolation. They often link into broader quality and production networks, feeding test results into Manufacturing Execution Systems (MES) or central databases for plant-wide visibility. This integration ensures that your hydro testing machine for pipe isn’t just producing results — it’s contributing high-value data to your quality ecosystem.

By moving test data into central systems, you also enhance traceability and make compliance reporting easier across audits and customer reviews.

Why PLC Controls Matter to Your Bottom Line

The benefits of PLC systems in a hydro testing machine for pipe are both technical and economic:

✔ Improved consistency means fewer retests and rejects

✔ Automated data logging saves time and reduces paperwork

✔ Enhanced safety monitoring protects operators

✔ Flexible profiles reduce setup errors and training time

✔ Integration capabilities feed quality data into strategic systems

For production teams, this translates into reduced downtime, better quality records, and a more predictable testing process — all of which support stronger customer confidence and smoother operations.

PLC systems are no longer a luxury in industrial testing equipment — they’re a core component of modern hydro testing machines for pipe. As manufacturers push for higher quality standards, tighter compliance, and more automated workflows, PLC-equipped machines give a real advantage. They don’t just control the machine — they give you repeatable results, defensible quality records, and safer operations.

If your plant is still relying on older, manually controlled hydro testing methods, it might be time to consider how PLC integration could streamline your quality inspection systems and enhance test accuracy. After all, in today’s competitive market, precision and reliability are everything.